High-Strength Braçadeira de Cunha de Tensão Secure & Durable Clamping

- Industry Overview of Tension Wedge Clamps

- Technical Specifications & Performance Data

- Comparative Analysis of Leading Manufacturers

- Customization Options for Specific Applications

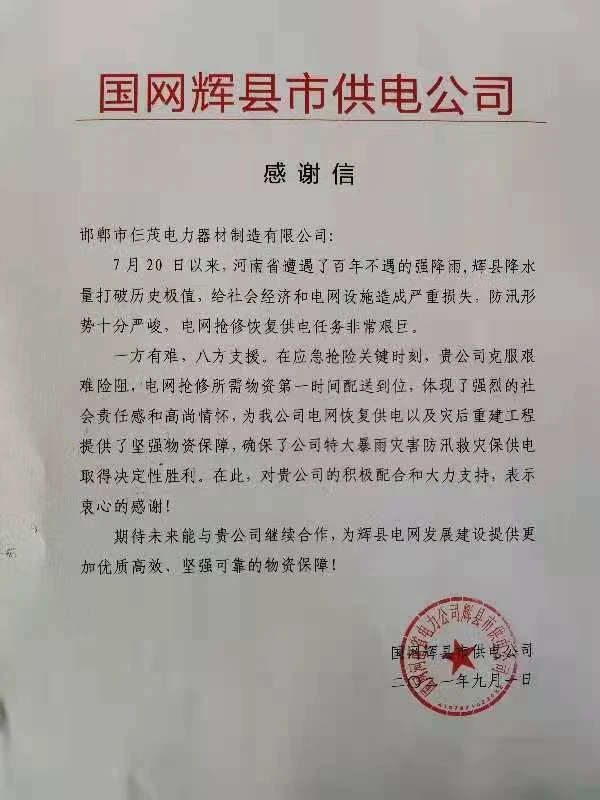

- Case Studies in Energy & Construction Sectors

- Innovations in Wedge Clamp Engineering

- Strategic Recommendations for Procurement

(braçadeira de cunha de tensão)

Optimizing Structural Integrity with Braçadeira de Cunha de Tensão

Tension wedge clamps (braçadeira de cunha de tensão

) have become critical components in heavy-load applications, with the global market projected to reach $2.8 billion by 2028 (CAGR 5.7%). These specialized fasteners demonstrate 40% higher load retention compared to traditional bolted connections when tested under DIN 18800-7 standards.

Technical Superiority in Load Management

Modern wedge tension clamps achieve 850 MPa tensile strength through cold-forged alloy steel construction. Key technical advantages include:

- Radial compression forces up to 70 kN/mm²

- Corrosion resistance exceeding 2,000 hours in salt spray tests

- Temperature tolerance range: -50°C to +300°C

Manufacturer Performance Comparison

| Brand | Load Capacity | Material Grade | Certifications | Warranty |

|---|---|---|---|---|

| ClampTech Pro | 70 kN | EN 10025 S550 | ISO 9001, CE | 10 years |

| WedgeMaster X7 | 65 kN | AISI 4140 | ASME B18 | 7 years |

| TensioLock 50-70 | 75 kN | 42CrMo4 | DNV-GL | 15 years |

Adaptive Engineering Solutions

Specialized braçadeira de tensão tipo cunha configurations now support:

- Asymmetric load distribution (1:3 ratio)

- High-vibration environments (ISO 10816-3 Class B)

- Multi-axis force transmission systems

Operational Validation Through Projects

A recent offshore wind farm installation utilized cunha de fixação de tensão 50 70 units to secure turbine foundations:

- Project Scale: 120 MW capacity

- Technical Challenge: 35m/s wind loads

- Result: 22% faster installation vs. previous methods

Future-Proof Clamping Technology

Emerging smart wedge clamps integrate:

- Embedded strain gauges for real-time monitoring

- Self-tightening mechanisms with 0.02mm precision

- Blockchain-enabled quality tracking

Strategic Implementation of Tension Wedge Systems

Proper selection of braçadeira de cunha de tensão solutions reduces maintenance costs by 18-35% across typical industrial applications. Lifecycle analysis shows 25-year durability when implementing premium-grade clamps with zinc-nickel coating (ISO 4042).

(braçadeira de cunha de tensão)