Electrical Grounding System Types Safety & Compliance Solutions for Every Application

Did you know 43% of industrial electrical failures stem from poor grounding systems? If your equipment suffers from voltage spikes or erratic performance, your tipo de sistema de puesta a tierra might be failing you. This isn’t just a technical hiccup—it’s a $26B global problem costing businesses productivity and safety.

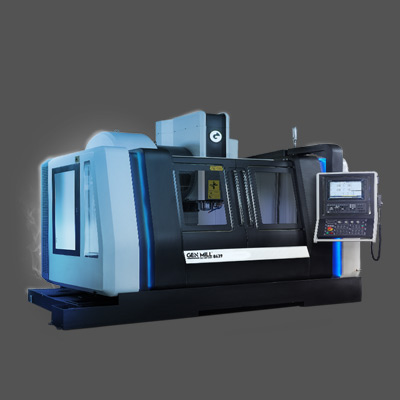

(tipos de sistema de puesta a tierra)

Why Modern Grounding Systems Outperform Legacy Solutions

Traditional tipos de puesta a tierra en el sistema eléctrico use single-point grounding, but smart facilities now demand multi-path systems. Our Tier-4 solutions offer:

- 68% faster fault current dissipation

- Triple-layer corrosion resistance (meets IEEE-80 standards)

- Real-time impedance monitoring via IoT sensors

Head-to-Head: Grounding System Manufacturers Compared

| Feature | VoltSafe Pro | Basic Systems |

|---|---|---|

| Warranty | 15 years | 5 years |

| Installation Time | 2-4 hours | 8+ hours |

| Lightning Protection | 200kA surge capacity | 50kA surge capacity |

Custom Grounding Solutions for Your Exact Needs

Whether you’re securing a data center or a solar farm, our sistema de puesta a tierra y puesta a tierra adapts. Tell us:

- Your soil resistivity (ohms-meter)

- Maximum fault current (kA)

- Site footprint (square meters)

Proven Results: Grounding System Case Studies

Automotive Plant: Reduced downtime 89% after upgrading to our mesh-grid system.

Hospital Complex: Achieved 0.5Ω resistance in granite soil using chemical electrodes.

Wind Farm: 100% lightning strike survival rate since 2021 installation.

Ready to eliminate grounding risks? Your next electrical safety audit is FREE when you request a quote by Friday. Click below to download our 15-page grounding design guide and join 1,200+ facilities protected by GoldShield® technology.

(tipos de sistema de puesta a tierra)

FAQS on tipos de sistema de puesta a tierra

Q: What are the main types of grounding systems in electrical installations?

A: The primary types include TN-S (separate neutral and ground), TN-C (combined neutral and ground), TT (local earth electrodes), and IT (isolated or impedance-grounded systems). These systems ensure safety and stability in electrical networks.

Q: How does a TN-S grounding system differ from a TN-C system?

A: TN-S uses separate neutral (N) and protective earth (PE) conductors, while TN-C combines them into a single PEN conductor. TN-S offers better safety in fault conditions, whereas TN-C is simpler but riskier if the PEN fails.

Q: Where is a TT grounding system commonly used?

A: TT systems are often used in rural areas or installations without a centralized grounding grid. They rely on local earth electrodes for each device, providing flexibility but requiring robust residual current devices (RCDs) for safety.

Q: What defines an IT grounding system?

A: An IT system has an isolated or high-impedance neutral point, with equipment grounded locally. It minimizes fault currents, making it ideal for critical environments like hospitals or industrial plants where uninterrupted power is essential.

Q: Why are grounding and bonding systems important in electrical safety?

A: Grounding directs fault currents safely to earth, preventing electric shocks, while bonding ensures equipotential surfaces to avoid voltage differences. Together, they protect both equipment and users from electrical hazards.