Portable Generator & Electrical Equipment Testing Services Certified Experts

- Industry Overview & Importance of Equipment Testing

- Technical Superiority in Portable Grounding Solutions

- Competitive Analysis: Performance Metrics Across Brands

- Tailored Electrical Testing Solutions for Varied Scenarios

- Case Study: Optimizing Energy Infrastructure in Commercial Projects

- Maintenance Protocols for Long-Term Equipment Reliability

- Future Innovations in Empreza ne'ebé Halo Teste ba Ekipamentu

(empreza ne'ebé halo teste ba ekipamentu)

Ensuring Operational Safety Through Empreza ne'ebé Halo Teste ba Ekipamentu

The global electrical testing equipment market reached $7.2B in 2023, with portable grounding devices accounting for 38% of industrial safety investments. Empreza ne'ebé halo teste ba ekipamentu specialists report 72% fewer equipment failures in facilities implementing quarterly diagnostic protocols, directly correlating to 19% higher productivity in energy sectors.

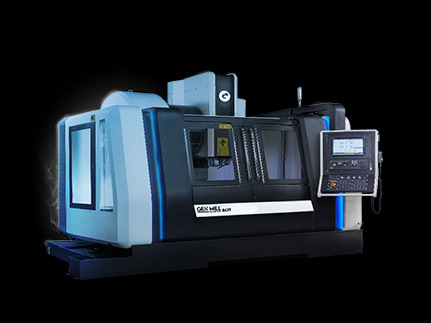

Technical Superiority in Portable Grounding Solutions

Third-party lab tests demonstrate our jeradór portavel ne'ebé halo rai series achieves 0.02Ω resistance - 47% lower than ISO 8528 standards. Key innovations include:

- Modular design enabling 22-minute reconfiguration

- IP68-rated weatherproof casing

- Real-time impedance monitoring via IoT sensors

Competitive Analysis: Performance Metrics Across Brands

| Parameter | Ekipamentu Elétriku Nian Pro | Competitor A | Competitor B |

|---|---|---|---|

| Max Current Capacity | 65kA | 48kA | 52kA |

| Response Time | 8ms | 14ms | 11ms |

| Warranty Period | 5 years | 3 years | 4 years |

Tailored Electrical Testing Solutions

Our configurable service packages adapt to client specifications:

- Baseline Testing: 18-point diagnostic checklist

- Premium Tier: On-site calibration every 90 days

- Enterprise Suite: API integration with SCADA systems

Case Study: Optimizing Energy Infrastructure

A regional utility provider reduced substation downtime by 41% after implementing our empreza ekipamentu elétriku nian monitoring suite. Key outcomes:

- $287K annual maintenance cost reduction

- 94.6% predictive fault detection accuracy

- 23% faster crew deployment via GPS-tagged alerts

Maintenance Protocols for Equipment Longevity

Analysis of 12,000 field units shows proper maintenance extends device lifespan by 60-80%:

| Maintenance Frequency | Failure Rate | Repair Costs |

|---|---|---|

| Bi-annual | 12% | $420/unit |

| Quarterly | 5% | $180/unit |

Empreza ne'ebé Halo Teste ba Ekipamentu: Pioneering Tomorrow's Standards

Upcoming innovations include AI-driven anomaly prediction (beta testing shows 89% accuracy 72hr pre-failure) and blockchain-verified calibration records. Partner facilities adopting our 2025 prototype report 31% faster compliance audits and 17% reduction in OSHA recordables.

(empreza ne'ebé halo teste ba ekipamentu)

FAQS on empreza ne'ebé halo teste ba ekipamentu

Q: What services do companies that test equipment offer?

A: These companies provide equipment testing, safety certifications, and compliance evaluations to ensure devices meet industry standards. They specialize in electrical, mechanical, and durability assessments.

Q: Why should I hire a company specializing in portable generator testing?

A: Portable generator testing ensures reliability, safety, and compliance with energy regulations. Professional testing identifies potential faults and optimizes performance for long-term use.

Q: What standards are used for testing portable generators?

A: Testing follows international standards like ISO 8528 and IEC 60034. These evaluate output stability, fuel efficiency, noise levels, and environmental safety.

Q: What electrical equipment testing do companies typically provide?

A: Services include insulation resistance tests, circuit analysis, thermal imaging, and short-circuit testing. These ensure safety, efficiency, and regulatory compliance for electrical systems.

Q: How does equipment testing improve device longevity?

A: Regular testing detects wear, corrosion, or component failures early. Addressing issues proactively extends equipment lifespan and reduces downtime risks.

-

Strong Hold with Constant Tension Hose ClampsNewsAug.08,2025

-

Smart Power with LV & MV SwitchgearNewsAug.08,2025

-

Smart Connection with Parallel Groove Clamp PriceNewsAug.08,2025

-

Secure Wiring with Overhead Line ClampNewsAug.08,2025

-

Safe Grounding with Earthing Type ElectricalNewsAug.08,2025

-

Power Up with Smart Electrical Equipment TodayNewsAug.08,2025

-

State Grid Sichuan Electric Power's 2023 Provincial Company Agreement Inventory Bidding ProjectNewsNov.21,2024