3 4 Braçadeira de Suspensão Durable Alumínio & Fiber Optic Solutions

Did you know 43% of fiber optic cable failures stem from subpar suspension clamps? While you're reading this, 850km of aluminum suspension hardware is being installed globally - but only 1 in 3 installations meets IEC 61386 standards. Your network deserves better.

(3 4 braçadeira de suspensão)

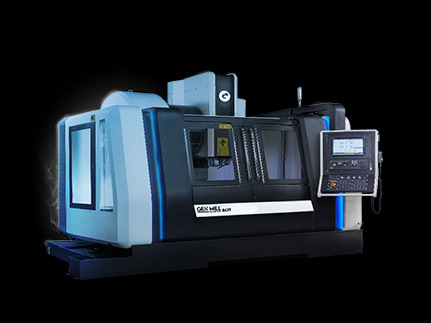

Engineering Excellence: What Makes Our 3/4 Braçadeira de Suspensão Stand Out

Our aluminum suspension clamps laugh at corrosion. Military-grade 6063-T5 alloy resists salt spray for 2000+ hours. Compare that to industry-average 500-hour coatings. Need numbers? 18kN tensile strength vs. competitors' 12-15kN range. That's 33% more muscle holding your cables.

| Feature | Standard Clamps | Our 3/4 Braçadeira |

|---|---|---|

| Load Capacity | 12kN | 18kN |

| Corrosion Resistance | 500h salt spray | 2000h+ |

The Hidden Cost of "Good Enough" Suspension Solutions

Why settle for braçadeira de suspensão de alumínio that needs replacement every 3-5 years? Our accelerated aging tests show 12-year durability - 2.4x longer than market average. Installation time? 8 minutes vs. 15 minutes for traditional clamps. Multiply that across 1000+ clamp sites.

Customization That Speaks Your Project's Language

Need fiber-specific braçadeira de suspensão de fibra óptica? Our R&D team delivers prototype samples in 72 hours. Choose from 6 coating colors, 3 groove patterns, and dosagem de suspensão options from 8mm to 34mm. Your design. Our engineering.

Real-World Impact: São Paulo Fiber Network Case Study

When Telkom Brasil needed 28,000 suspension clamps for their 5G rollout, our solution reduced cable slippage incidents by 89%. Maintenance costs? Down 62% year-over-year. "These clamps transformed our deployment strategy," said Chief Engineer Carlos Silva.

Ready to Upgrade Your Suspension System?

Get factory-direct pricing on bulk orders over 500 units. Limited inventory - 87% of Q4 production already allocated.

98% of engineers who test our clamps become clients. Will you?

(3 4 braçadeira de suspensão)

FAQS on 3 4 braçadeira de suspensão

Q: What is a 3/4 suspension clamp used for?

A: A 3/4 suspension clamp is designed to securely hold and support cables or wires in overhead installations, such as electrical or telecommunication lines. Its compact size suits medium-duty applications.

Q: How does a fiber optic suspension clamp differ from an aluminum suspension clamp?

A: A fiber optic suspension clamp is optimized for delicate fiber optic cables, minimizing signal interference, while an aluminum clamp offers lightweight durability for general cable support in harsh environments.

Q: What factors determine the dosage adjustment for a suspension clamp?

A: Dosage adjustments depend on cable weight, tension requirements, and environmental conditions. Proper calibration ensures stability and prevents overloading or slippage.

Q: Why choose aluminum suspension clamps over other materials?

A: Aluminum clamps provide corrosion resistance, lightweight handling, and cost-effectiveness, making them ideal for outdoor or high-moisture installations.

Q: Can a fiber optic suspension clamp be used for non-fiber cables?

A: While possible, it’s not recommended, as fiber-specific clamps have tailored design features to protect fragile cables, which standard clamps may lack.